Glas transition temperature

The glass transition temperature (TG) is the temperature at which the adhesive becomes brittle. It is important that the application temperature is distinctly above the TG of the adhesive (e.g. resealable bags that are stored in the fridge or freezer as it can prevent a safe reclosure of the bag).

Hard adhesive

Term usually used to characterize highly cohesive PSA tapes.

Advantages (compared to soft adhesives):

higher holding power withstands

higher sustained loads good temperature resistance

less edge picking

improved die cuttability

Disadvantages:

low initial tack and adhesion;

requires higher contact pressure

not suited for rough surfaces

Hot melt pressure-sensitive adhesive

Types of pressure sensitive adhesive that can be coated without use of solvents or water. Today PSA tapes based on synthetic rubber as well as acrylics are available for hot melt coating.

Humidity resistance

Moisture or even humidity can affect the performance of an adhesive. Especially if applied under wet or very humid conditions the adhesive absorbs the humidity, which leads to reduced adhesion performance. This effect occurs especially with water-based acrylics, which should not be used under those conditions.

In general a PSA tape is humidity resistant when it resists contact with humid air or even water without negative effects on the adhesion properties

All acrylics have a good humidity resistance. Humidity can damage paper liners and lead to “bubbles” on the surface of the tape. Basically, filmic liners are more dimensionally stable than paper ones.

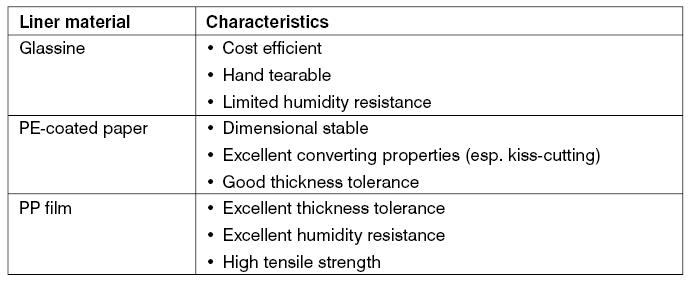

liner

Anti-adhesive material which covers the adhesive on almost all d/s and some s/s tapes and prevents the adhesive from sticking to itself. The liner is used as a protection aid during handling/processing and storage. Most commonly used liner types are

1. Paper liners (e.g. Glassine paper, PE-coated paper, Clay-coated paper)

2. Film liners (e.g. PP, PET, PE) Silicone is used as release system to avoid adhesion between liner material and adhesive.

migration

The molecular movement over a long period of time of an ingredient from one surface to another when both are in contact. Migration may occur between tape components and the surface to which applied. Some plastic films (e.g. PVC) contain plasticizers which are apt to migrate into the tape adhesive, causing the adhesive to soften. Other ingredients like foaming, vulcanisation, age-resistant agents used for flexible seals migrate into the tape and can compromise the bond.

Non-polar substrates

Critical surfaces to adhere to due to low surface energy. The lower the surface energy the lower the molecular attraction to the adhesive (adhesion). Typical materials are polyolefins such as PP and PE, but also PS, EVA and many powder painted surfaces. By surface pretreatment (e.g. corona treatment) the polarity can be modified to achieve higher surface energy and improved adhesion. Use of primers will also act as adhesion promoters.

Outgassing

Amount of chemical ingredients evaporating from adhesives (e. g. monomer residues, solvents, etc.) especially under elevated temperature conditions. Often a concern in the Automotive, Aerospace and Electronics industries, where chemical residues could affect e. g. electric circuits.

Polar substrates

Uncritical surfaces to adhere to due to high surface energy. On these substrates the high molecular attraction between adhesive and substrate leads to increased adhesion. Most common materials are PET, PC, PVC, ABS, steel, aluminum, glass etc.

Primer

A coating applied to a surface (e. g. backing or a substrate) prior to the application of an adhesive, improving bond performance between backing and adhesive or between tape and substrate